Container terminal operations generate vast amounts of data from various sources, providing a valuable foundation for analysis, optimization, and predictive decision-making. This data-driven approach enhances operational visibility, allowing terminal operators to monitor and manage key processes with greater accuracy. By leveraging advanced analytics, terminals can improve planning efficiency, optimize resource allocation and refine simulation models to predict future scenarios ultimately leading to better operational outcomes.

A robust data analysis framework strengthens the decision-making process at all levels of management, offering actionable insights that support both strategic and real-time operational decisions. For instance, predictive analytics can help anticipate bottlenecks, improve berth planning, and optimize gate operations, reducing delays and enhancing overall terminal performance.

DATA INTEGRATION

The data fueling these insights comes from multiple sources, including the TOS which manages vessel, yard, and gate operations; the Vehicle Booking System (VBS), which tracks truck appointments and traffic flow; and other operational platforms such as IoT sensors, equipment telemetry, CMR, M&R systems, HR, Billing and Financial records. Integrating these diverse datasets into a centralized data warehouse enables seamless aggregation, cleansing, and transformation of data, facilitating more sophisticated analytics and machine learning applications.

AI powered BI

Prediction plays a crucial role in informed decision-making, particularly for operational managers. For example, DSP has developed DATAVIEW a Business Intelligence solution that can forecast the expected number of trucks arriving at the terminal over the next 30 days, as well as their distribution across gate working hours. These forecasts allow terminal managers to proactively allocate resources, ensuring there are no shortages or inefficiencies in manpower, equipment, or gate capacity.

In other words, by harnessing big data and advanced AI-driven methodologies, container terminals can transition from reactive to proactive decision-making, reducing inefficiencies, improving turnaround times, and enhancing overall competitiveness in an increasingly dynamic logistics formatting environment.

DSP and TIC4.0

The TIC Committee has been actively working to standardize digitalization within the container terminal environment, aiming to establish unified frameworks and best practices that enhance interoperability, efficiency, and data-driven decision-making. “DSP is a key contributor to TIC4.0’s mission, playing an active role in the development of the TIC language that enables seamless integration between different systems while ensuring semantic data integrity. By aligning its solutions with TIC4.0 standards, DSP is driving interoperability and fostering a truly connected terminal ecosystem where data flows efficiently and retains its full meaning and context. Solutions like DATAVIEW exemplify how adopting common industry digital standards are essential for the cargo industry to fully exploit big data analytics and accelerate the adoption of 4.0 technologies. By embracing these standards, the industry can move from fragmented digital environments to a more cohesive and intelligent operational framework, unlocking new levels of efficiency and insight.” says Boris Wenzel, President of TIC4.0.

As a key member of this committee, DSP has been contributing its expertise and industry experience to drive these digital transformation efforts forward.

DSP has been a pioneer in aligning its solutions and products with TIC standards, ensuring full compliance while continuously adapting to evolving industry requirements. By integrating these standardized digital frameworks, DSP not only enhances operational efficiency but also facilitates seamless collaboration between different stakeholders in the container logistics ecosystem. Through its proactive approach, DSP remains at the forefront of innovation, leveraging emerging technologies such as artificial intelligence, IoT, and advanced analytics to create smarter, more connected container terminals.

DATA GOVERNANCE

A fundamental requirement for any solution in the container terminal environment is its ability to enforce robust data governance, data ownership, and multi-level access control. Given the diverse range of stakeholders involved—spanning terminal operators, shipping lines, trucking companies, and regulatory authorities—ensuring secure, role-based access to data is critical.

Each stakeholder operates within a different scope of the business, requiring a solution that can accommodate multiple user roles with distinct access privileges. The system must be capable of defining and enforcing granular access controls, ensuring that each entity can only view, modify, or manage the data relevant to their specific role. This not only strengthens security and compliance but also enhances operational transparency and trust among all participants in the ecosystem.

By integrating advanced data governance frameworks, such solutions can safeguard sensitive information, streamline workflows, and ensure regulatory compliance while fostering a collaborative yet secure digital environment for container terminal operations.

ABOUT DATAVIEW

“Due to the growing need for an integrated Business Intelligence (BI) tool – says Marco Fehmer DSP CEO, DSP developed DATAVIEW, a powerful platform designed to aggregate and analyze data from various sources within the container terminal. DATAVIEW seamlessly integrates this information into a centralized data warehouse, enabling terminals to access near real-time, live, and historical data in an interactive and visually appealing manner”.

One of DATAVIEW’s key features is its highly customizable reporting capability. Users can create, modify, and share reports tailored to their specific operational needs, ensuring data-driven decision-making at every level. Additionally, its integration with Power BI enhances the user experience, providing a flexible and efficient environment for building rich, fast, and interactive reports with advanced visualizations.

The core component is the customizable ETL (Extraction, Transformation and Loading) process, based on an abstract view of operational data, that makes the solution act as TOS agnostic and enables the integration with various and heterogenous data sources available in application constellation of the terminal. The transformation step translates the raw transactional data into a format suitable for analysis by cleaning, enriching, aggregating, and structuring the data into a star schema with fact and dimension tables.

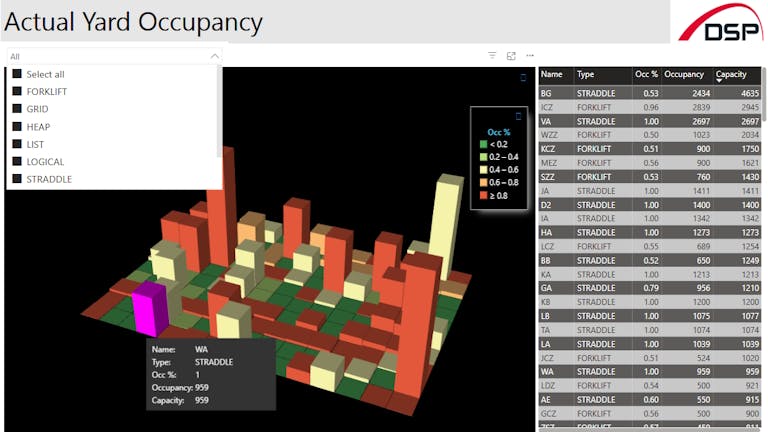

At DSP, we're committed to continuously improving our DATAVIEW Business Intelligence solution to meet the evolving needs of container terminals worldwide by introducing enhancements that provide deeper insights, improved operational visibility, and more powerful analytics capabilities. Our latest versions introduce comprehensive performance tracking features. The Equipment report now offers unprecedented depth, showcasing hourly moves and operator performance metrics, detailed job step charts illustrating average times across critical operational states and enhanced visibility into equipment productivity. We've introduced new reports and features that give terminal managers unprecedented operational transparency: live quayside reporting with configurable productivity highlights and previous shift details, appointments tracking with detailed transaction insights, yard volumes occupancy analysis for all and special units.

DATAVIEW TIC4.0 KPIs

The TIC4.0 choice, as a purpose of standardizing digitalization and the adoption of unified frameworks, has materialized in the implementation of new dashboards with the agreed definitions of KPISs such as terminal-wide throughput about the full terminal, the gate, the yard and the rail operations, the carrier visit turnaround time and the carrier productivity tracking for cargo operations.

DATA INTEGRATION ENHANCEMENTS

One strategic area of evolution concerns the data integration enhancements through the combination of the traditional ETL processes with event-based techniques and stream process platforms. Traditional scheduled extraction operates on fixed intervals, processing data in discrete batches according to predefined schedules. Although DATAVIEW extraction, transformation and loading procedures are highly optimized, this traditional approach inherently introduces latency between data creation and availability, which means there's always a delay between when events occur and when they become available for analysis. Currently, this delay corresponds roughly to the average time to complete a move on a vessel making the calculation of KPIs accurate for being used in live operational dashboards, but it might not be enough for other contexts.

In contrast, event-based streaming processes data continuously as events occur, enabling near real-time data availability and analysis. In the next DATAVIEW versions, the traditional ETL processes will be coupled with extraction approaches based on Change Data Capture (CDC) patterns to allow the implementation of near real-time dashboards with more responsiveness capabilities and/or with more detailed visualizations. There are however additional challenges to be considered in implementing event-based extraction processes. For example, recovery procedures are straightforward in the scheduled approach, typically involving batch replay from known checkpoints. Stream processing requires more sophisticated consistency mechanisms to handle unbounded data flows, including exactly once processing guarantees and out-of-order event management.

Another aspect is that the event-based approach allows distributing in time the computational load for the data processing, including the data transformation cost, as the logical consequence of the captured event occurrences. By using a stream process platform, such as Kafka, it is possible to broadcast the transactional to analytical results coming from the combined ETL process to multiple distributed consumers. This approach is applicable to the CDC patterns as well as to the scheduled extraction by interpreting the last one as a new event. In this scenario distributed consumers may act as big data collectors by transforming and storing the information to a on-premises or in cloud persistent repository. This simplifies the integration with the most well-known cloud services such as Amazon S3, Amazon Redshift, Azure Data Lake Storage Gen2, Azure Blob Storage, Google Cloud Storage, Snowflake, Databricks enabling new reporting, visualization, advanced analytics and ML applications.

PREDICTIVE ANALYSIS IN DATAVIEW

A standout feature of DATAVIEW is its predictive analytics capability, which empowers users with forward-looking insights. Through analytical reports terminal operators and managers gain a clear understanding of past events and emerging trends, enabling them to anticipate and address potential operational challenges.

By leveraging predictive analytics, DATAVIEW transforms terminal operations from reactive to proactive, optimizing workflows, reducing bottlenecks, and ultimately enhancing overall efficiency and service reliability.

AUTHOR BIO _ Nello Nellari

Nello Nellari serves as Software Engineering Team Director at DSP, leading product development and IT integration initiatives for maritime and intermodal transportation solutions. With an extensive background spanning academic research and multinational software development, he specializes in distributed systems and software architecture. Nello holds an MS in Computer Science.

AUTHOR BIO _ Majid Samar

Majid Samar is an AI & Data Science Specialist at DSP, with expertise in machine learning, predictive analytics, and optimization. He develops solutions for container terminal operations, enhancing efficiency and automation. Passionate about reinforcement learning and time series analysis, he drives informed decision-making and intelligent automation in industrial settings.

https://www.porttechnology.org/technical-papers/business-intelligence-to-empower-strategic-decisions-and-optimise-terminal-operations/